Home » Freight Car Components » Wear Prevention

Wear Prevention

Amsted Rail’s Hollube® and Hollamax™ wear prevention products are made with an advanced plastic that outlasts steel and reduces wear up to 88%. Whether it’s wear on brake beams, center plates or bowls, couplers, yokes or brake rods, Amsted Rail’s wear prevention products can save thousands of dollars in replacement costs through built-in lubricity.

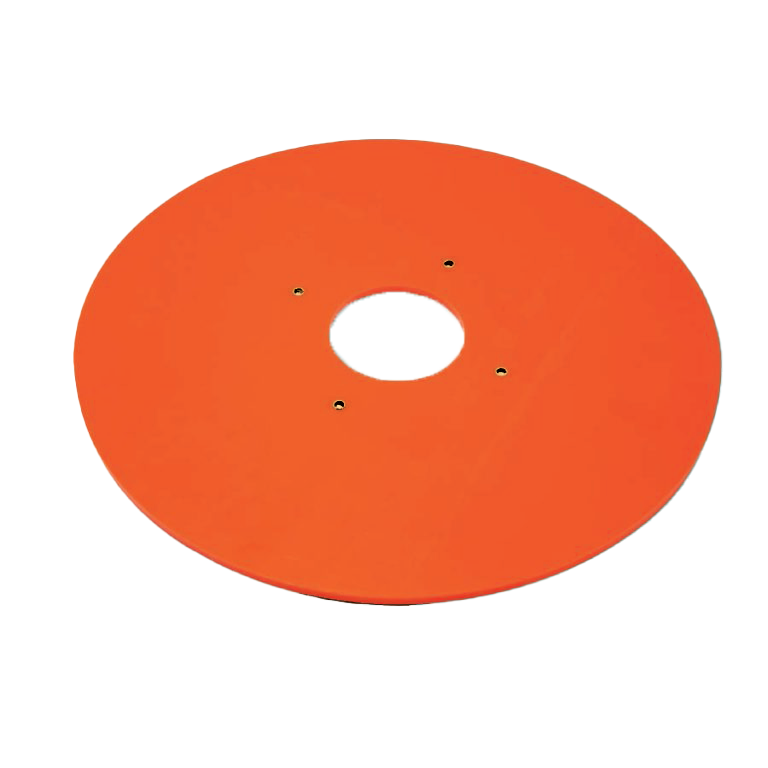

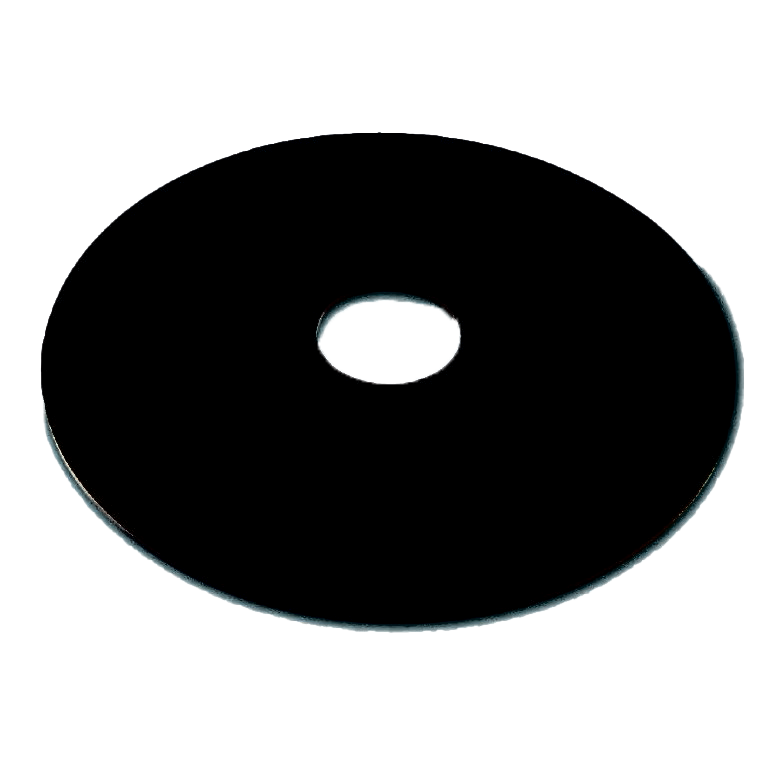

WE-1010-1016 Center Bowl Horizontal Liners

Available with ground rivets (WE-1016) or without ground rivets (WE-1016-1), these liners prevent center plate and center bowl horizontal surface wear, never require lubrication, and weigh less than metallic liners. With simple drop-in installation, no welding is required. AAR approved M-976.

WE-1014-XLS, WE-1016-XLS Center Bowl Horizontal Liners

Made of Extended Life Hollube and specially designed for rail loads of 286,000 lbs, these liners eliminate risk of static buildup, providing constant ground to trucks without the use of metal grounding pins. They prevent center plate and center bowl horizontal surface wear without the need for lubrication. With simple drop-in installation, no welding is required. AAR approved M-976.

WE-2016, WE-2016J Center Bowl Horizontal Liners

These liners prevent center plate and center bowl horizontal surface wear, never require lubrication, and weigh less than metallic liners. With simple drop-in installation, no welding is required. AAR approved M-976.

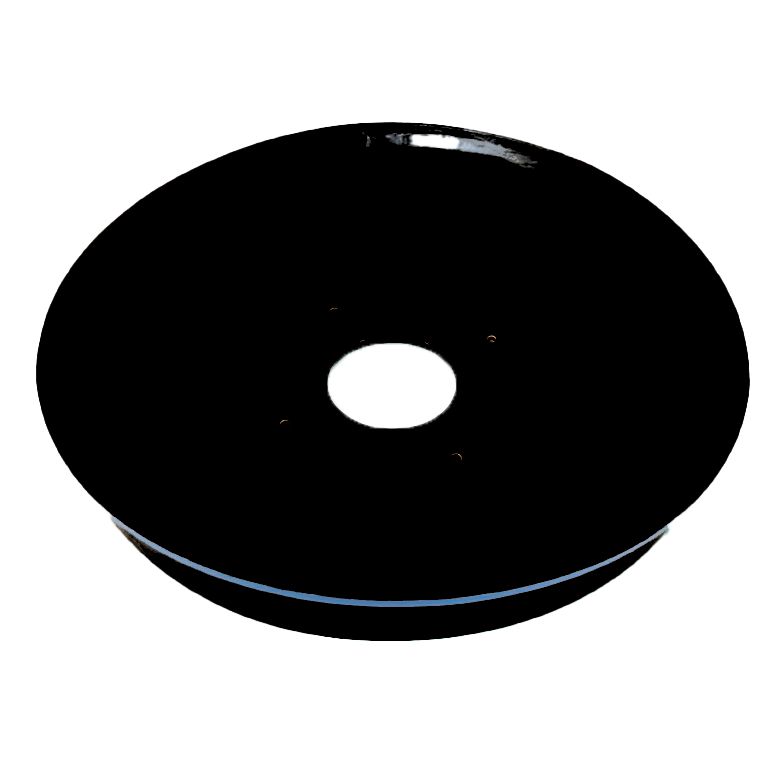

WE-2416, WE-2416J Premium Center Bowl Wear Liners

With enhanced cold flow resistance and heavy duty forged construction, Amsted Rail’s premium center bowl wear liners are designed for high mileage. These liners prevent center plate and center bowl wear, never require lubrication, and weigh less than metallic liners. With simple drop-in installation, no welding is required. AAR approved M-976.

WE-2516J Heavy Duty Center Bowl Wear Liners

Made of advanced Hollamax material, Amsted Rail’s heavy duty bowl wear liners are designed for high mileage and heavy loads. These liners prevent center plate and center bowl wear, never require lubrication, and weigh less than metallic liners. With simple drop-in installation, no welding is required. AAR approved M-976.

WE-3001 Rear Yoke Support Wear Eliminators

Ideal for high-mileage applications, these rear yoke support wear eliminators prevent wear on yoke strap and yoke strap support. No welding is required for simple installation, and lubrication is not needed.

WE-4004 Coupler Carriers for Rotary Dump Cars

Available in four sizes for maximum flexibility in adjusting coupler height, these coupler carriers eliminate wear on coupler shanks and carrier baskets. Weighing only 9 pounds, they save 18 pounds of weight compared to steel. 10-year/1,000,000-mile warranty when installed on new cars. AAR unconditionally approved.

WE-4110 Weld-On Coupler Carrier Wear Plates

Available in a variety of thicknesses, these wear plates are designed to prevent wear on coupler shanks. Long-life Hollube material bonded to a steel backing provides excellent wear resistance and easy weld-on installation that doesn’t require removing the coupler. AAR unconditionally approved.

WE-4340, WE-4340-XL Universal Coupler Carrier Wear Plates

These wear plates are designed with longer legs to provide insurance against loss. They fit T-type carriers on newer cars and older box-type carriers, eliminating the need to stock multiple wear plates for older and newer cars. With simple drop-in installation, no welding is required. Patented and AAR approved.

WE-4900 Coupler Carriers for F-Type Draft Sills and Rotary Dump Cars

With no metal-to-metal contact, these coupler carriers eliminate wear on coupler shanks and carrier baskets. Car sets weigh 42-46 pounds less than steel carriers, providing higher load capacity. Available in four sizes for maximum flexibility in adjusting coupler height. Patented and AAR approved.

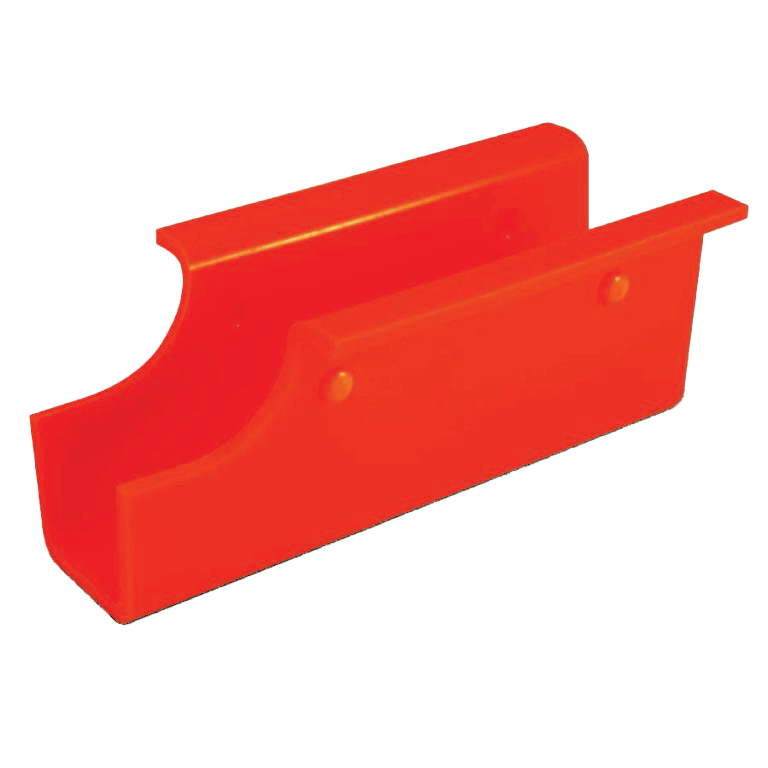

WE-5000 Brake Rod Bracket Wear Eliminators

Available for a variety of bracket sizes, these wear eliminators prevent wear on brake rods and brackets and reduce friction in braking systems. Easy, snap-on installation.

WE-5001-5004 Brake Rod Wear Protectors

Available in any length required, these wear protectors prevent war on brake rods and brackets and reduce friction in braking system. Easy installation only requires snapping on wear eliminator then tack-welding retainers.

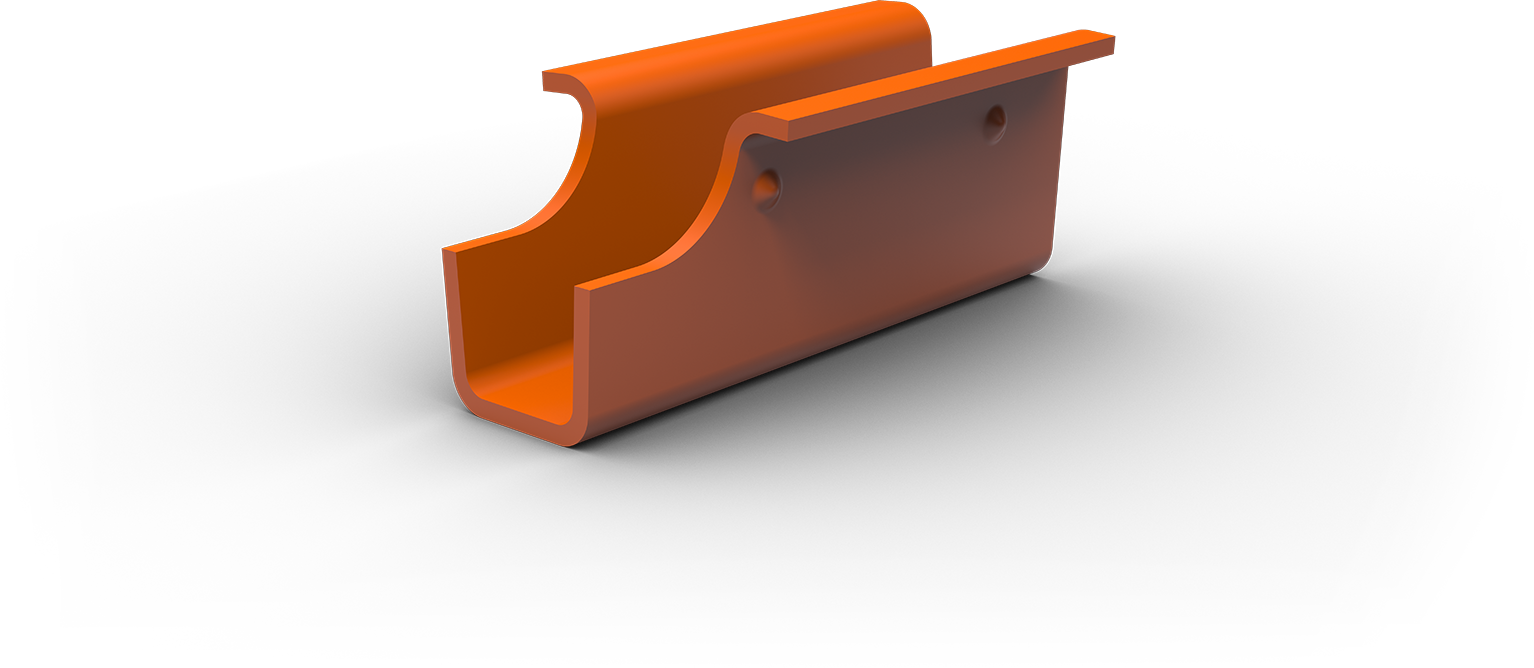

WE-5505 Brake Beam Wear Eliminators

Amsted Rail’s most economical brake beam guide wear eliminator reduces brake shoe consumption, eliminates wear on brake beam guides and is lightweight, preventing brake beam droop and reducing wheel flange wear.

WE-5510-XL Heavy Duty Brake Beam Guide Wear Eliminators

Made with advanced Hollamax material, the heavy duty construction is ideal for high mileage, heavy gross axle load applications. These wear eliminators provide superior cold flow resistance, reduce brake shoe consumption and eliminate wear on brake beam guide. The design accepts both standard and “diagonally corrected” brake beams.

WE-5525 Alignment Plus™ Brake Beam Guide Wear Liners

In real-world tests, the Alignment Plus brake beam guide wear liners have shown reduced asymmetric wheel wear and exceptional wear liner service life. Improved brake beam alignment lowers the occurrence of thin flange wheel defects, and less lateral shift than standard brake beam liners extends wheel wear life. Liners can be placed into all four truck guide pockets and still allow brakes to be applied properly.