Home » Freight Car Components » Energy Management and Draft Sills

Energy Management and Draft Sills

Amsted Rail has expertly designed a variety of end-of-car energy management devices to provide full protection from start to stop, reducing in-train and coupling impact forces and protecting railcars and lading.

Learn why an Amsted Rail Active Draft Cushioning Unit system is the optimal system for your freight cars

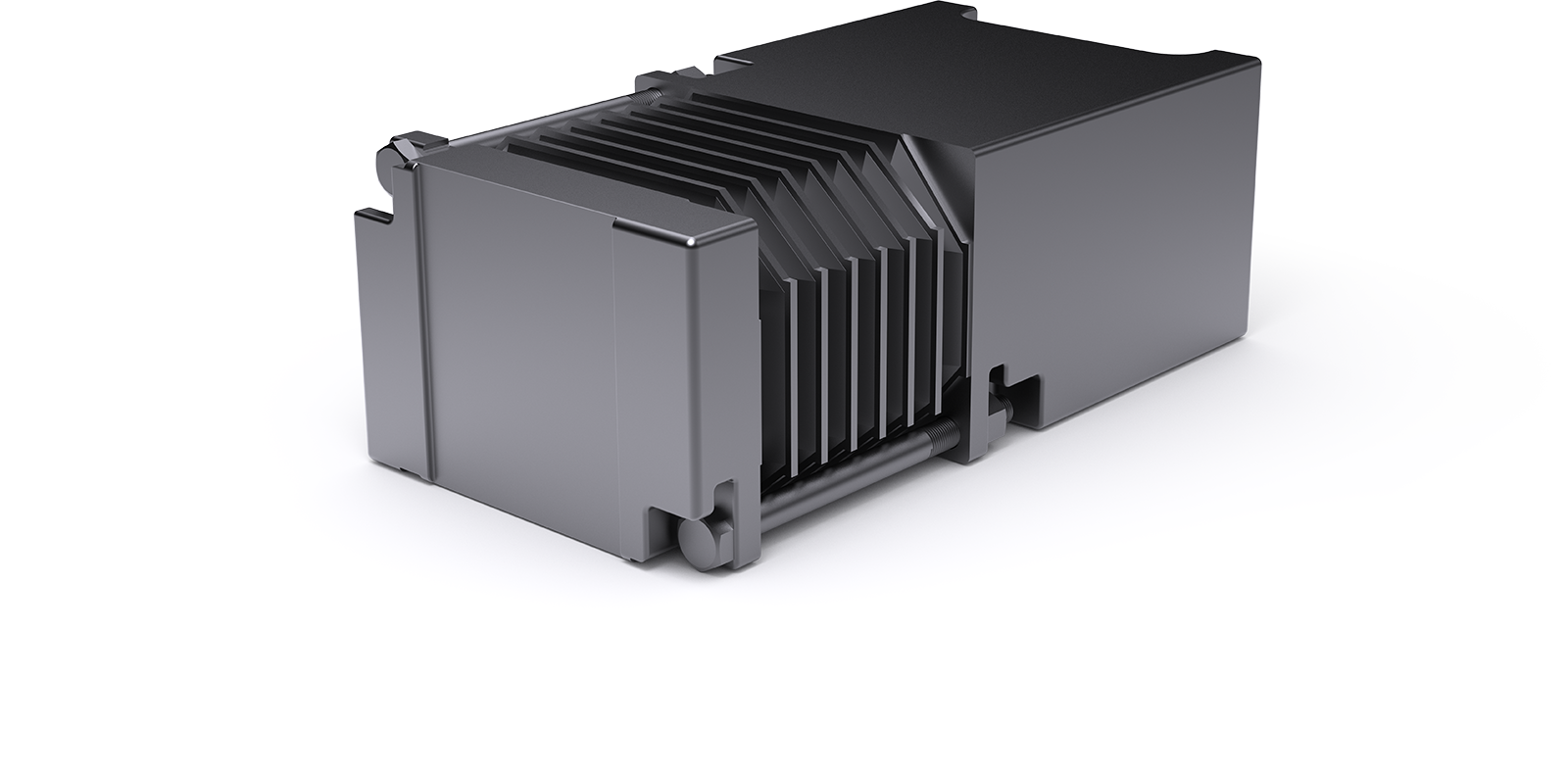

Endurance 325™ Draft Gear

Utilizing the AAR standard yoke and follower, the Endurance 325 draft gear offers protection, performance and durability in one lightweight package, with an optimized housing design for lower stresses and longer life. AAR M-901E unconditionally approved.

Twin Pack® Draft Gear

Providing service-proven protection worldwide, the Twin Pack draft gear is designed to reduce impact force by as much as 65%, limiting the potential for railcar damage. Available for all coupler types and AAR unconditionally approved.

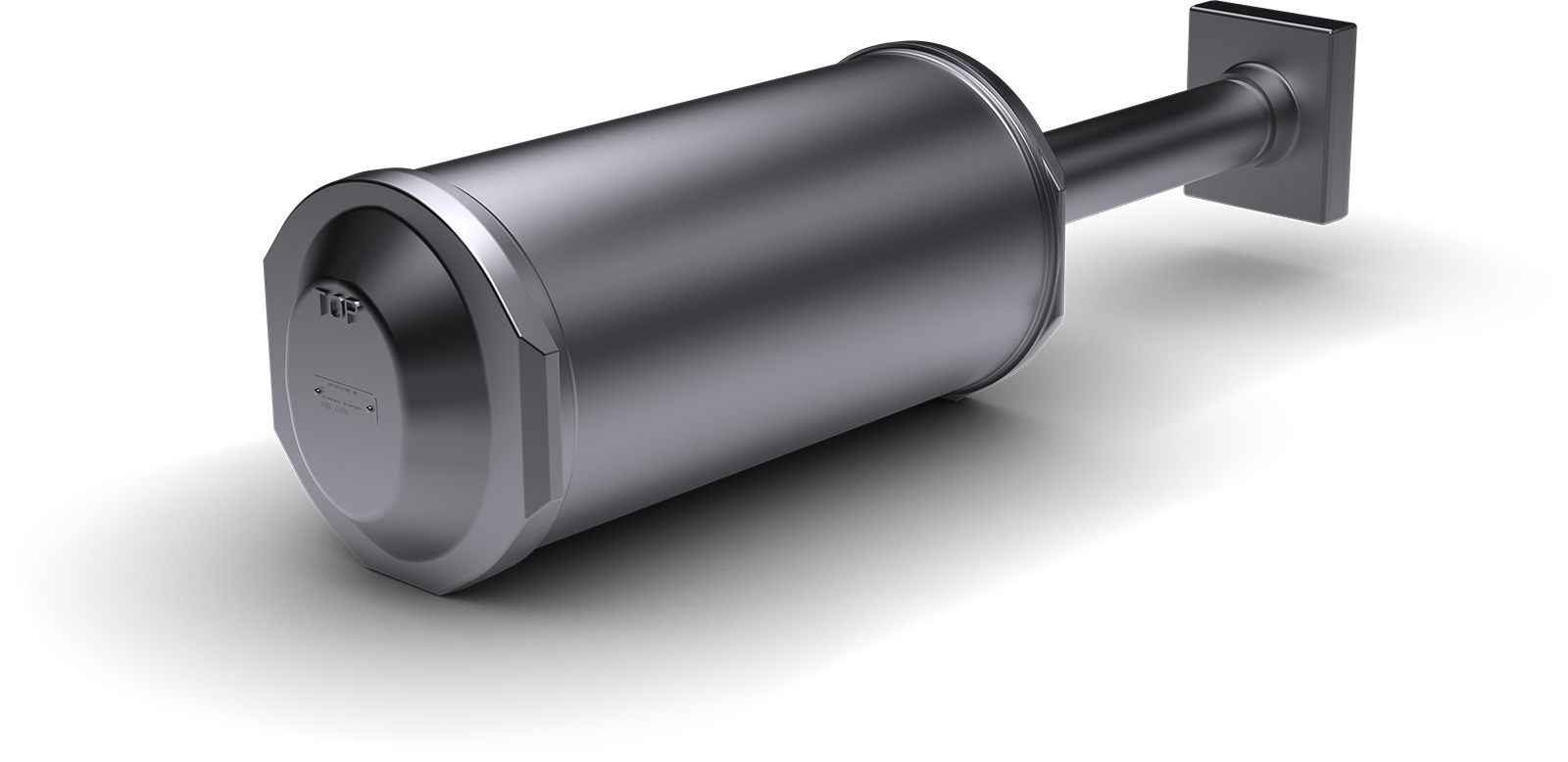

DraftMaster™ Draft Gear

The DraftMaster draft gear is the next generation of freight draft gears built for the rigors of heavy hauling. Tailored for iron ore service and indexing operations, this draft gear seamlessly integrates into all existing or new railcars, requiring no changes to draft gear pockets, couplers, yokes or followers. The DraftMaster draft gear is derived from technology that has already been proven in service for decades and is currently utilized in applications around the world.

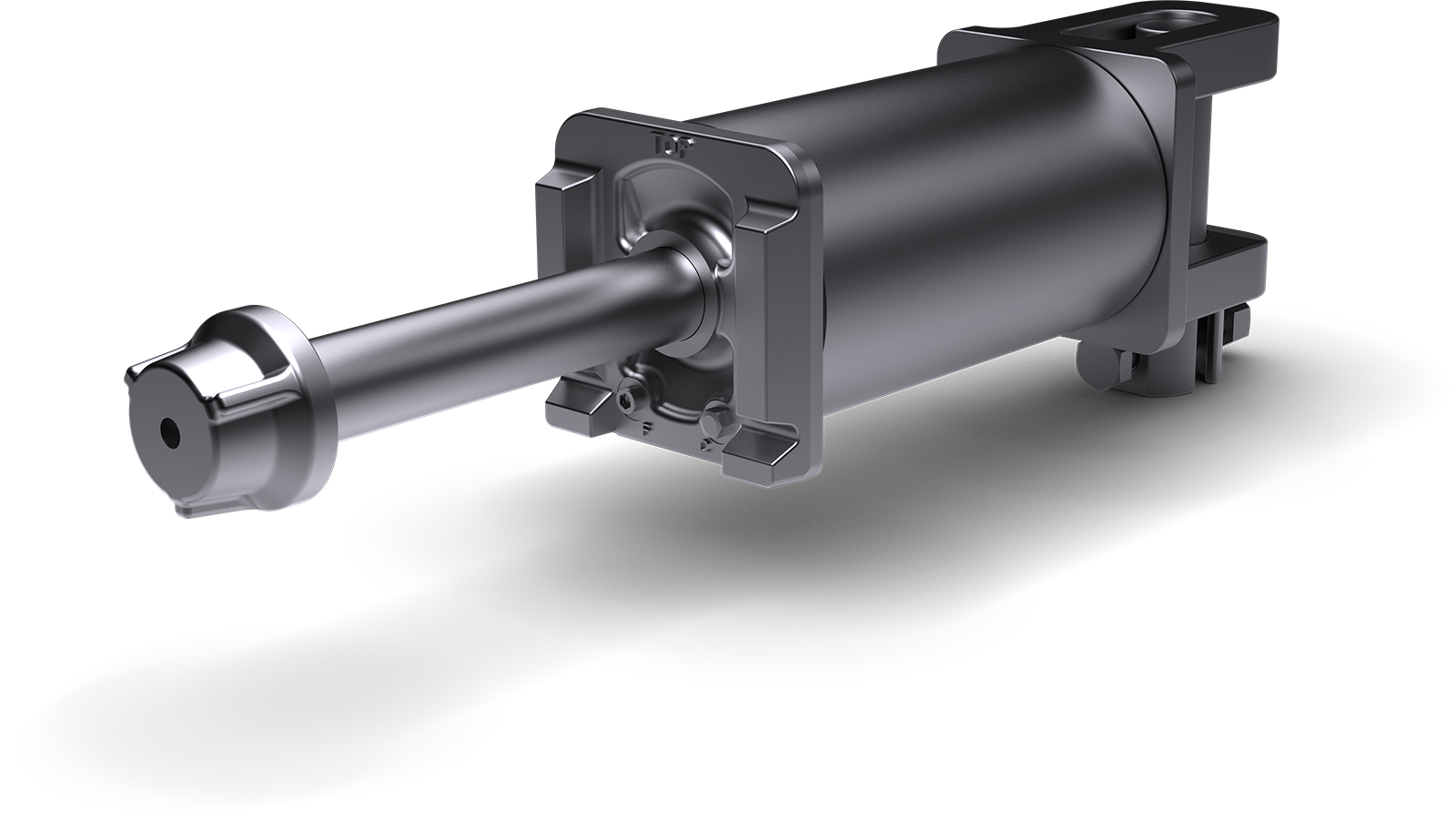

Standard Cushioning Units

Designed with both yard impacts and train force reduction in mind, Amsted Rail’s standard cushioning units provide the most cushioning in the buff direction and are best for railcars that carry sensitive lading. AAR unconditionally approved.

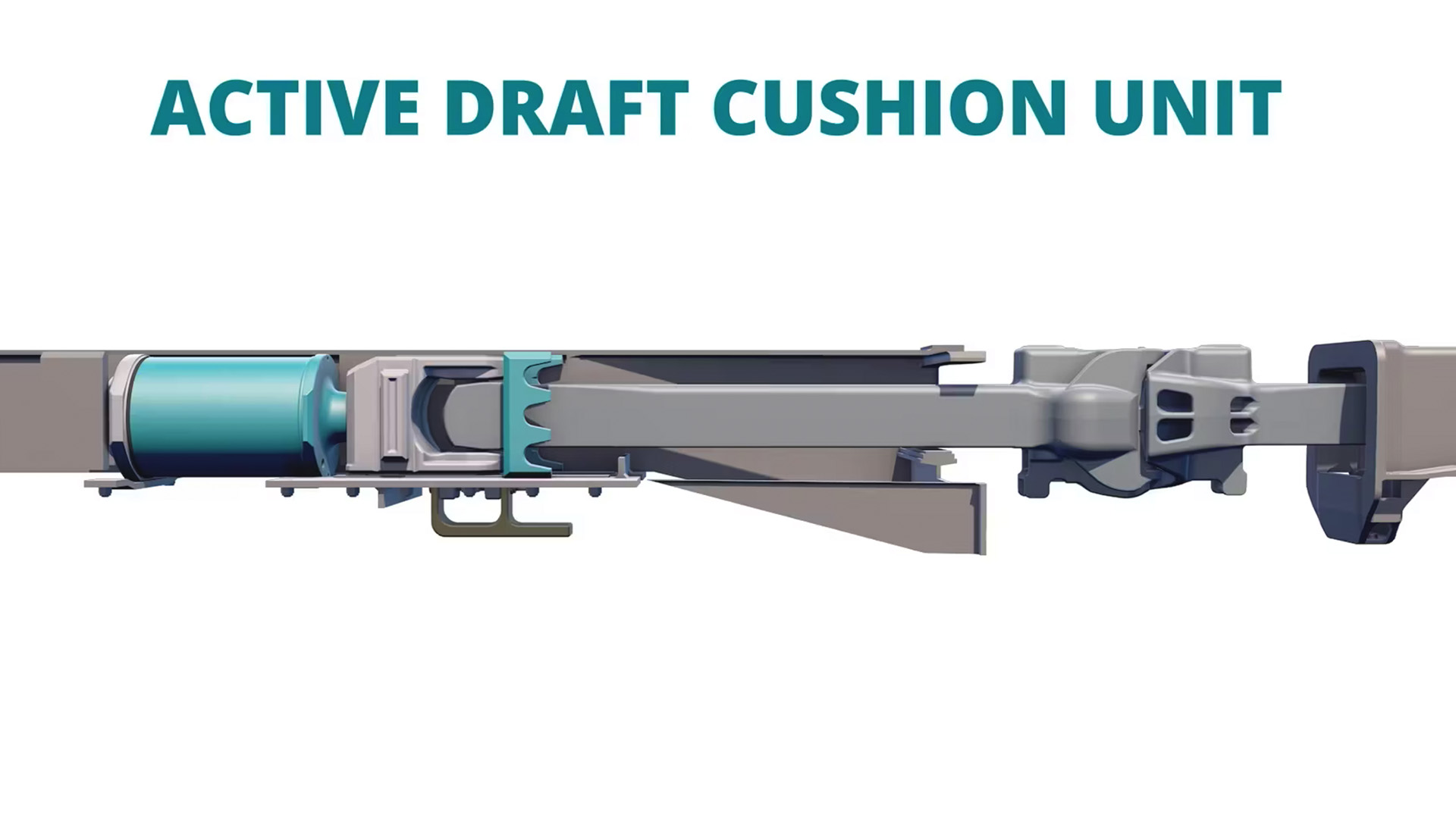

Active Draft Cushioning Units

Amsted Rail’s active draft cushioning units are designed to maintain a neutral position at all times, ready to attenuate in-train draft shocks, providing optimal protection against both buff and draft forces that can cause damaging

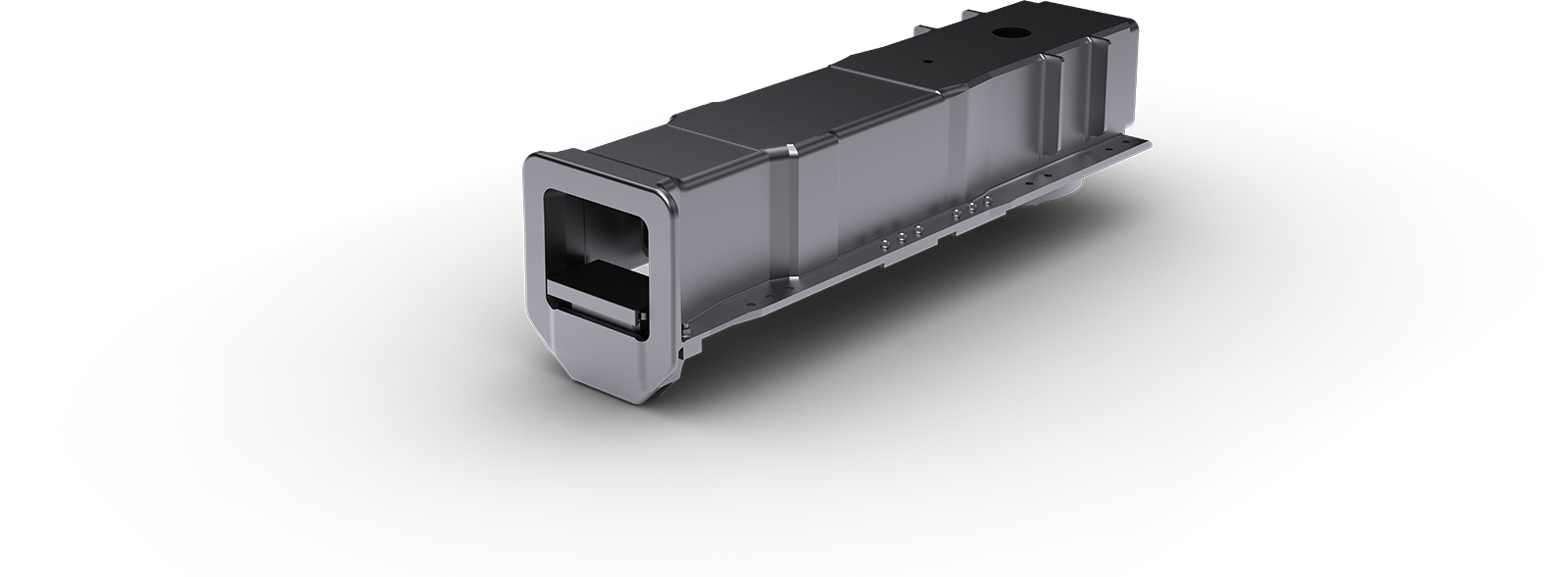

Draft Sills

Amsted Rail’s integral cast draft sills are built to be lighter, stronger and longer-lasting than fabricated sills. They lower impact stresses in the railcar structure while reducing empty car weight by nearly 300 pounds. AAR approved.