Telematics

Amsted Digital Solutions

Amsted Digital Solutions® brings the complex ecosystem of freight rail logistics, typically managed in spreadsheets and multiple third-party systems, into one user-friendly platform. Our advanced railcar fleet management solution integrates the industry’s leading onboard telematics for remote monitoring of a railcar’s health and status in real time.

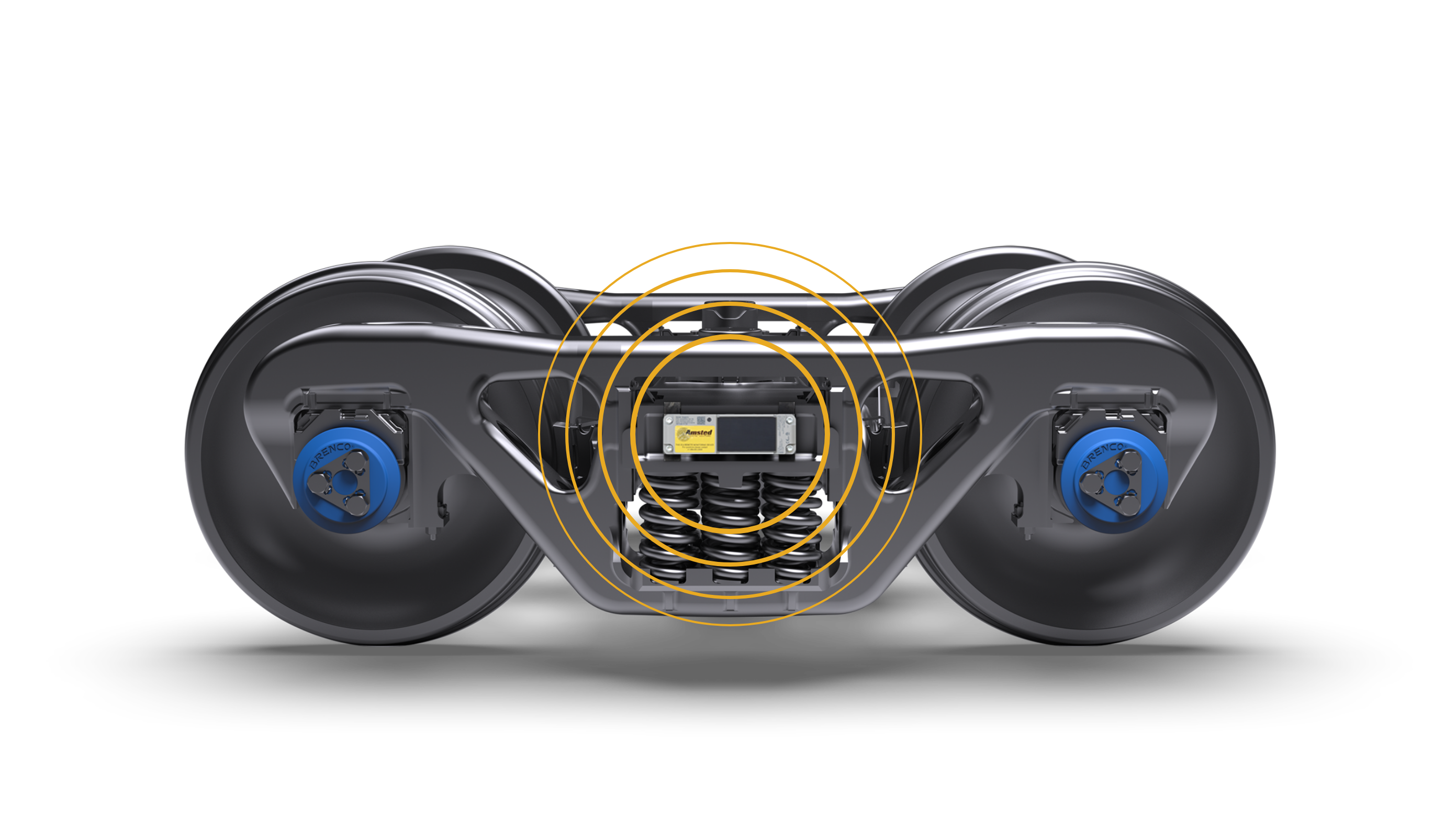

IQ Series™ Gateway with Bogie IQ® Technology

One device. No external sensors. Innovation unleashed.

Amsted Digital Solutions’ innovative IQ Series gateway is a maintenance-free, low-power onboard telematics device built to perform in freight rail’s harshest operating environments. With powerful built-in capabilities paired with advanced machine learning technology, the IQ Series gateway virtually eliminates the need for specialized external sensors.

Amsted Digital Solutions' leading IQ Series onboard telematics technology obtains certified status from RailPulse

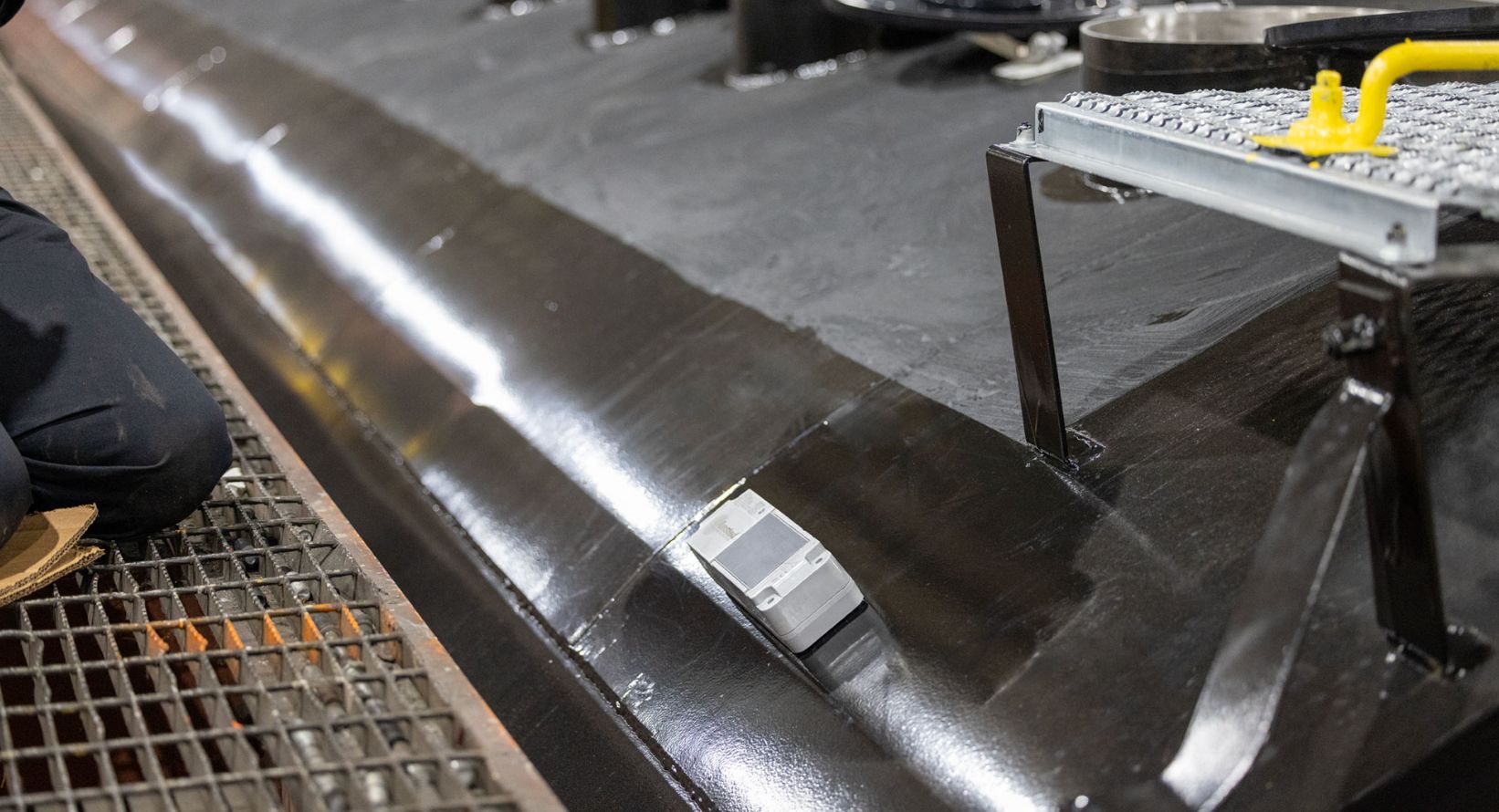

Body-Mounted Gateway

When mounted on the body of virtually any railcar, the IQ Series gateway provides:

Dynamic ETA calculations and geofence entry and exit alerts for first- and last-mile validation

Accurate Load Status in Motion (LSiM) for precise loaded and empty mileage calculations

Impact detection

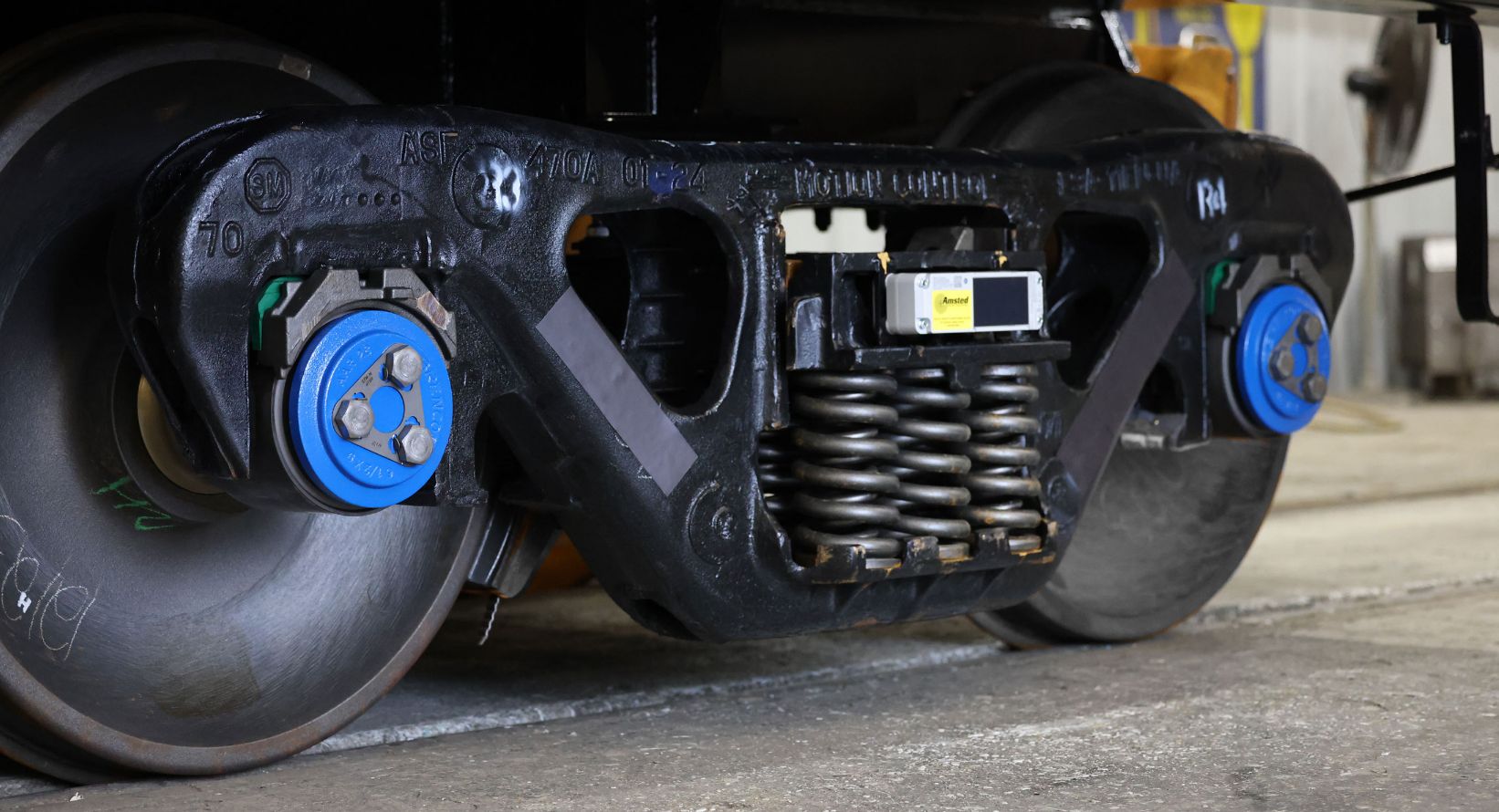

Bogie-Mounted Gateway

When mounted on one or both trucks of a railcar and configured with Bogie IQ technology, the IQ Series gateway provides real-time onboard health monitoring in addition to all of the data available from the body-mounted gateway. These include:

Stationary loading/unloading detection

Monitoring of wheel health

Real-time monitoring of brake slide events

Impact differential detection, a feature that identifies which end of a railcar took the initial impact during a coupling event

Easily upgradeable for longevity and adaptability

As new features become available, existing installed gateways can be updated through simple, over-the-air firmware upgrades to instantly unlock new capabilities, eliminating the need to schedule a railcar to facility for physical replacements.

Shipment Management

Maximize shipping efficiency with fast, accurate intelligence

Amsted Digital Solutions offers a fast and efficient shipment management solution that goes beyond simply tracking railcars. With access to information across 600+ railroads, users can sort and search in various ways, providing unrivaled operational intelligence. Quickly find the required cargo, track shipments by fleet, origin, destination, and railcar status, and receive automatic route time estimates. Our solutions can help companies be more profitable by reducing shipment cycle times, mitigating costs such as detention and freight fees, and maximizing overall productivity.

Asset Management

Keep your assets on track with real-time management and monitoring

Amsted Digital Solutions simplifies asset management by providing a comprehensive profile for each railcar, including cargo capacity, ownership, lease status, maintenance records, and more. Users can set up alerts to stay on top of important events, such as lease expirations and required servicing. Add Amsted Digital’s onboard technology for even more visibility, monitoring the health conditions of wheels, brakes and more in real time.

Brought to you by the global leader in heavy haul rail

Together, Amsted Rail and Amsted Digital Solutions combine nearly 150 years of excellence in rail component design and manufacturing with today’s leading-edge telematics technology and software capabilities.

Amsted Digital Solutions works closely with Amsted Rail to deliver ground-breaking technology, such as our latest Bogie IQ technology. Amsted Digital leverages Amsted Rail’s research & development facilities across North America, including an impact test track, a bearing test facility and a proprietary multi-axis load machine (MAL), to support Amsted Digital’s innovations and product developments.