FREIGHT SYSTEMS &

COMPONENTS BUILT TO LAST

Amsted Rail builds virtually everything under the railcar, from wheels, axles and bearings to brake systems, end-of-car energy management systems and more. In many categories, we are the industry leader. In every category, we set the standard for proven performance and reliability.

AMSTED DIGITAL SOLUTIONS

TELEMATICS & PLATFORM

Amsted Digital Solutions® revolutionizes freight rail logistics with an all-in-one platform designed to help fleets streamline operations, enhance visibility and optimize maintenance.

Amsted Digital’s proprietary Supply Chain Visibility™ software features a comprehensive suite of shipment, asset and operations management tools.

Onboard devices provide real-time insights into the health and status of railcars and their key components.

For rail fleets looking for an outsourced option, our team of highly skilled fleet management professionals can handle the heavy lifting while your team focuses on other critical areas of your business.

Transit

Solutions

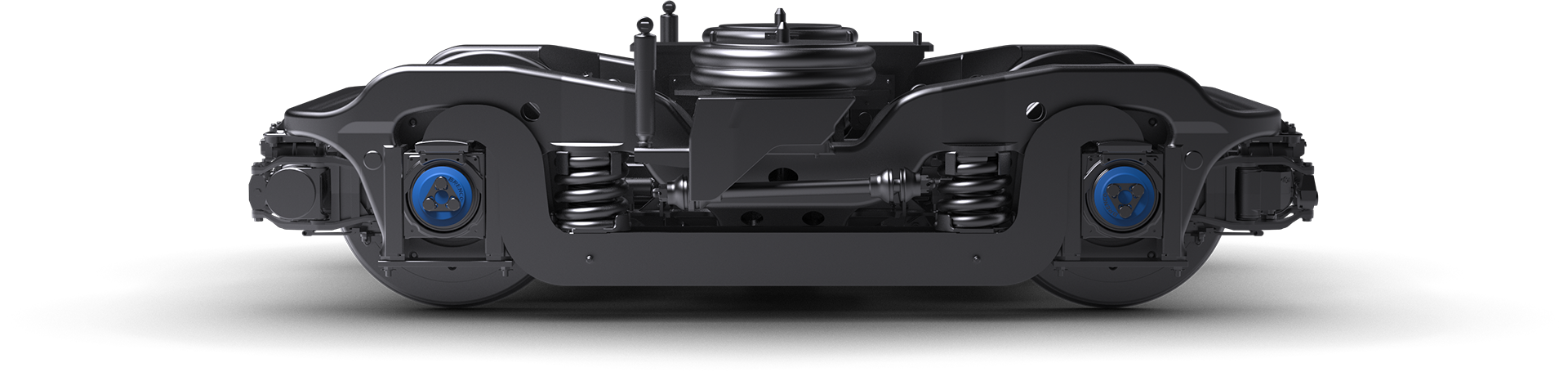

Headquartered in Chicago, Illinois, Amsted Rail designs, engineers, tests and manufactures our entire suite of transit products in the United States. Our state-of-the-art facilities are spread throughout the heart of America, combining our operational expertise with a manufacturing footprint that continues to grow with the country’s expanding rail needs.

Our complete offering of transit rail products includes fully assembled, powered or unpowered bogie systems and components, and end-of-car components expertly designed to work as a system.

Inspection & overhaul services are available for most manufacturers’ bogies and end-of-car systems, reconditioned to “like new” specifications.

Internal modeling, dynamic simulation expertise, and in-house testing facilities allow Amsted Rail to validate and deliver customer-specific solutions.

Our People Keep the World Moving

Nick Hughes

Manager, Emerging Technologies

Greenville, South Carolina, USA

Nick Hughes has been a vital force within Amsted Rail’s digital operations group for the past eight years. His journey at Amsted Rail is marked by his unwavering commitment to bridging the gap between cutting-edge technology and business innovation.

Elaina Hodges

Process Manager

Granite City, Illinois, USA

Elaina Hodges embarked on her journey at Amsted Rail with a clear vision of what she wanted in her career. Thanks to internship experience during college, she knew after graduation she wanted to work in a foundry, and she knew that company culture was very important.

Javier Peterson

Maintenance Supervisor

Hammond, Indiana, USA

Starting from the ground floor as a laborer, Javier Peterson steadily climbed the ranks, transitioning from a machine operator to a quality inspector before joining the maintenance department as lead maintenance multi-craft. With 15 years at Amsted Rail and almost two years in his current position, Javier’s story is one of determination, skill and patience.

Join a Winning Team Where Success is Always In Motion

At Amsted Rail, we take pride in our rich culture of innovation and ownership that has propelled us to the forefront of the industry. Our employees are our greatest asset, and we are committed to creating a work environment that offers everyone the chance for success, growth and happiness—on and off the job.